How Automation Is Reshaping Workflows in Technical Industries

Automation has moved far beyond simple task replacement and has become a structural element of modern technical industries. By 2025, engineering, manufacturing, IT, and energy sectors rely on automated systems not only to increase efficiency, but also to improve accuracy, safety, and long-term scalability. This shift is changing how teams operate, how decisions are made, and how technical professionals interact with their work.

Automation as a Foundation for Modern Technical Operations

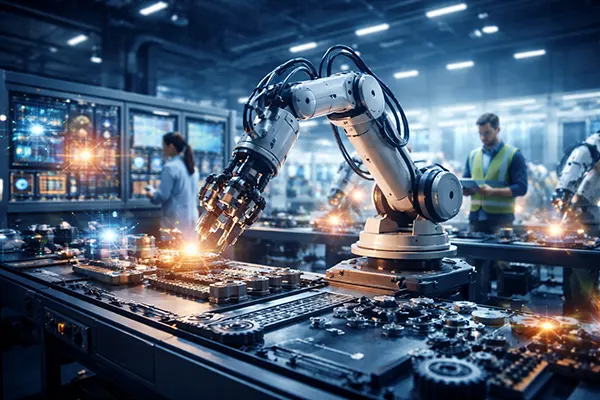

In technical industries, automation now forms the backbone of daily operations. Industrial controllers, automated testing environments, and data-driven monitoring systems handle repetitive and high-risk processes with a level of consistency that manual work cannot match. This allows organisations to maintain stable output even under complex conditions.

Another key impact lies in process standardisation. Automated workflows reduce variability caused by human error and differing skill levels. In sectors such as electronics manufacturing or cloud infrastructure management, this standardisation ensures predictable outcomes and easier compliance with regulatory and quality requirements.

Automation also supports faster adaptation to change. When workflows are defined through software logic rather than manual routines, updates can be deployed quickly. This flexibility is particularly important in industries facing rapid technological change, such as telecommunications and renewable energy systems.

From Manual Control to Intelligent Process Management

Traditional manual control required constant human supervision and intervention. Modern automated systems increasingly rely on intelligent process management, where sensors, analytics, and rule-based logic work together to regulate operations in real time. Engineers now oversee systems rather than directly controlling each step.

By 2025, predictive analytics has become a standard component of automation in technical environments. Systems can identify potential faults before they occur, allowing maintenance teams to act proactively. This reduces downtime and extends the lifespan of critical equipment.

This shift changes the role of technical specialists. Instead of focusing on routine adjustments, professionals concentrate on optimisation, system design, and strategic improvements. Automation does not remove expertise from the process; it reallocates it to higher-value tasks.

Impact of Automation on Workforce Structure and Skills

Automation reshapes workforce structures by redefining job responsibilities rather than simply reducing headcount. Routine and repetitive tasks are increasingly handled by machines, while human roles evolve towards supervision, analysis, and decision-making. This transition is visible across software development, industrial engineering, and network administration.

Technical roles now require a broader skill set. Understanding how automated systems operate, how data flows through them, and how to interpret outputs has become essential. As a result, continuous training is no longer optional but a core element of professional development in technical fields.

Collaboration patterns also change. Automation connects departments through shared systems and data, reducing silos. Engineers, data analysts, and operations managers often work with the same automated dashboards, creating a more integrated approach to problem-solving.

New Skill Demands in Automated Technical Environments

One of the most significant changes concerns technical literacy beyond traditional engineering knowledge. Professionals are expected to understand scripting, system integration, and data interpretation even if their primary background lies elsewhere. This hybrid competence improves communication between teams.

Soft skills gain importance alongside technical expertise. As automation handles execution, humans focus on evaluation and judgement. Clear communication, critical thinking, and the ability to assess system limitations become decisive factors in operational success.

By 2025, companies investing in structured reskilling programmes show greater resilience. Rather than treating automation as a disruption, they use it as a framework for long-term workforce development, aligning human capabilities with automated processes.

Automation and Long-Term Efficiency in Technical Industries

Efficiency gains from automation extend beyond speed and cost reduction. Automated systems enable consistent quality control, detailed performance tracking, and data-driven optimisation. These factors contribute to sustainable growth rather than short-term productivity gains.

Energy efficiency is another important outcome. Automated control systems optimise resource usage by adjusting operations in real time. In sectors such as data centres and industrial production, this leads to measurable reductions in energy consumption and operational waste.

Automation also improves safety standards. Hazardous tasks can be executed by machines, while monitoring systems detect anomalies faster than human observation. This reduces workplace risks and supports compliance with increasingly strict safety regulations.

Scalability and Reliability Through Automated Systems

Scalability is one of the strongest arguments for automation in technical industries. Automated workflows can be replicated and expanded with minimal disruption, allowing organisations to grow without proportional increases in operational complexity.

Reliability improves as automated systems operate continuously within defined parameters. Unlike manual processes, they do not suffer from fatigue or inconsistency. This reliability is essential for critical infrastructure, including power grids, communication networks, and industrial control systems.

Looking ahead, automation serves as an enabling layer for further innovation. Technologies such as advanced robotics, machine learning, and autonomous systems build upon existing automated foundations, ensuring that technical industries remain adaptable and competitive beyond 2025.